CRYSTAL CORK was born as a project in 2016, in order to meet the needs of the market to minimize the number of bottles with organoleptic deviations, whether caused by 2,4,6-trichloroanisole (TCA) or by other molecules (OFF FLAVOURS) .

It was precisely the need to be able to eliminate even the off-flavors to let BELIN CORK go the way of sensory analysis.

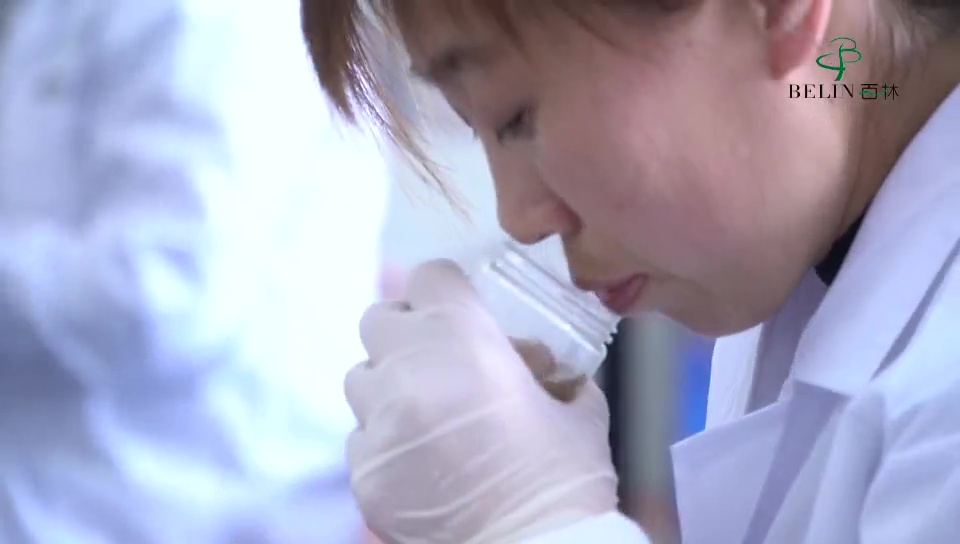

The first tests for the selection of the employees to be used in the sensory analysis have shown a natural high sensory sensibility and therefore in a short time a panel of 12 people has been created.

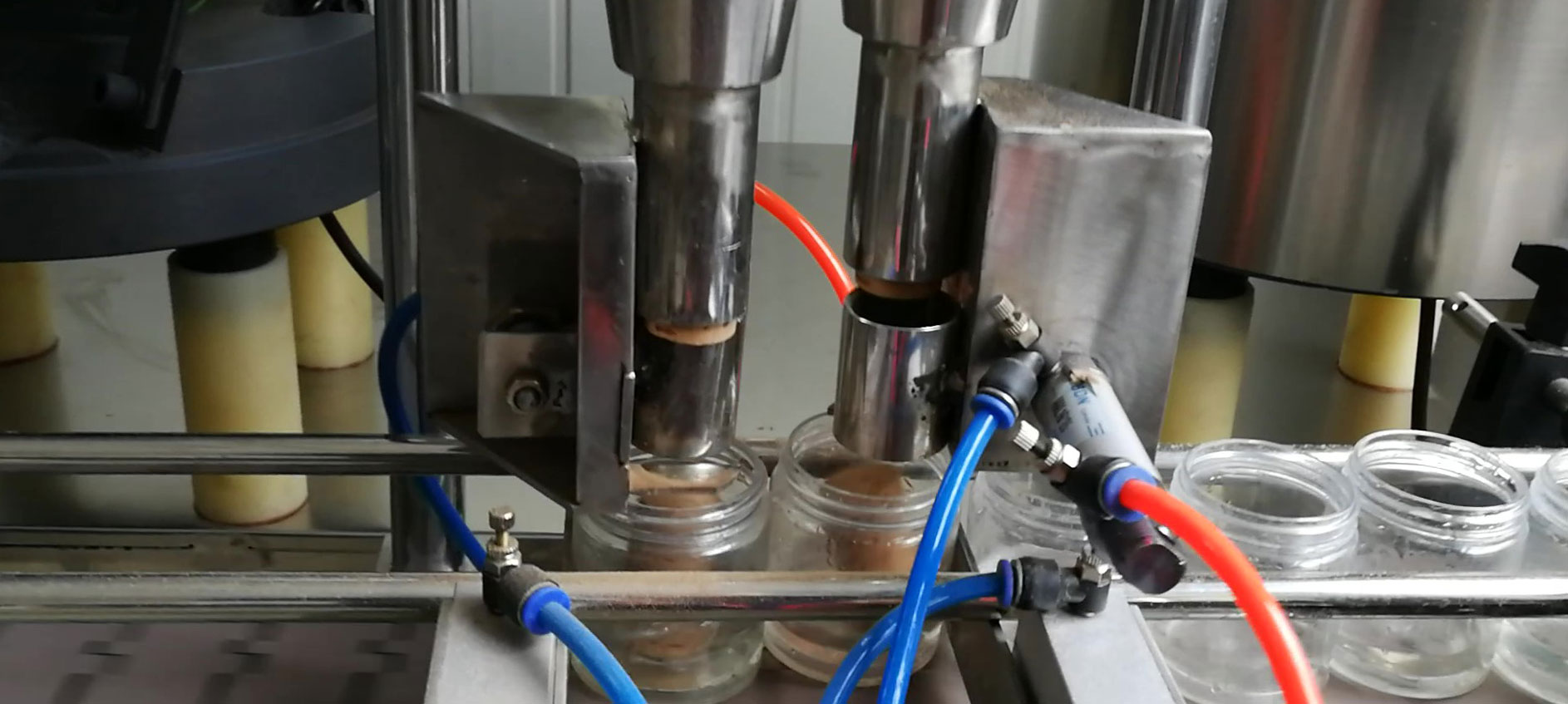

The samples are prepared by placing a single cork stopper in an airtight plastic container together with 25 ml of water. The test water is treated with a dechlorination and deionization process, then it is re-mineralized and sterilized.

The presence of salts inside the water is necessary to increase the polarity of the solution and, consequently, to increase the volatility of the molecules extracted from cork, which by their nature are not very polar and therefore have a poor affinity with the polar solution.

The hermetically sealed samples are kept for 24 hours in an air-conditioned environment at standard room conditions.

The automation of the sample preparation line made it possible to significantly reduce idle times, managing to create 90-minute work cycles, followed by at least 30 minutes of different activity for each employee, in order to optimize sensitivity and attention of the person.

The process of sensory selection is rather simple, as it does not involve the recognition of the foreign smell but only the detection of its presence. The cork, by its nature, has its own smell which becomes, after a few samples, the baseline for the sense of smell and is therefore attenuated: all the samples that will subsequently have a deviation from the baseline will be discarded. A mental mechanism of 1 and 0, rather simple and not very weary from the point of view of attention.